Using energy-resolved neutron imaging to spot the difference

The ability

of neutrons to penetrate relatively thick metal objects allows the use of

various non-destructive testing techniques when other more conventional methods

(e.g. laboratory X-ray) cannot be implemented. Neutron imaging with thermal and

cold neutrons provides unique contrast and is often used to study internal

structure and the presence of defects in various metal samples, as well as the

distribution of hydrogen-containing substances within metals, water in proton

exchange membrane fuel cells, coolant in heat pipes, diesel in fuel injectors

and many others. At the same time, neutron diffraction is widely used for

studies of crystallographic properties as the wavelengths of thermal and cold

neutrons are comparable to lattice parameters.

The ability

of neutrons to penetrate relatively thick metal objects allows the use of

various non-destructive testing techniques when other more conventional methods

(e.g. laboratory X-ray) cannot be implemented. Neutron imaging with thermal and

cold neutrons provides unique contrast and is often used to study internal

structure and the presence of defects in various metal samples, as well as the

distribution of hydrogen-containing substances within metals, water in proton

exchange membrane fuel cells, coolant in heat pipes, diesel in fuel injectors

and many others. At the same time, neutron diffraction is widely used for

studies of crystallographic properties as the wavelengths of thermal and cold

neutrons are comparable to lattice parameters.

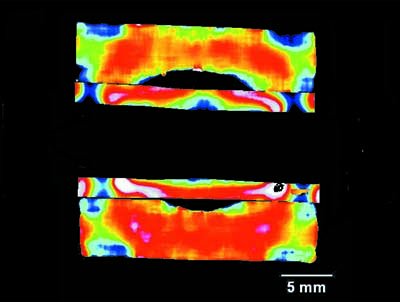

The recent development of high-resolution neutron counting detectors capable of simultaneous measurement of >250 000 spectra in combination with the state of the art beamlines at pulsed neutron sources provide the possibility to map both crystallographic properties and elemental composition in various samples with relatively high spatial resolution. Put to the test the technique could hold the key to the non-destructive investigation of the microstructure and elemental composition and uniformity within welds.

In a recent publication [Tremsin et al. (2016). J. Appl. Cryst. 49, doi:10.1107/S1600576716006725] a group of scientists from Japan, the UK and the USA demonstrate the possibilities of energy-resolved neutron imaging to study some microstructural features and the bulk distribution of elemental composition in two different sets of dissimilar alloy welds. They also demonstrate the possibility of mapping the distribution of various elements within the welds through resonance absorption imaging with epithermal neutrons.