The unique characteristics of X-ray free-electron lasers (XFELs) have opened new experimental frontiers for the life and materials sciences. This has enabled the development of novel methods, such as serial femtosecond crystallography (SFX), fluctuation X-ray scattering (FXS) and several X-ray spectroscopies, which have transformed atomic resolution molecular imaging and ultrafast materials characterization (Chapman et al., 2011; Kraus et al., 2018; Bergmann et al., 2021; Konold et al., 2023). The XFELs' ultrashort X-ray pulses with exceptional peak brilliance and spatial coherence allow us to record molecular movies of chemical and biological processes with unprecedented spatial and temporal resolution. These exciting possibilities come at a hefty price, however: the sample typically gets blown up or heavily modified by the intense X-ray dose (Neutze et al., 2000; Stan et al., 2016). Although the diffraction-before-destruction principle still allows damage-free data collection at room temperature at XFELs (Chapman et al., 2011), the sample must be swiftly and efficiently replaced before the next X-ray pulse arrives. While the limited availability of most biological samples already complicates the technical realization of this requirement, the introduction of MHz-rate XFELs further exacerbates the challenge (Wiedorn et al., 2018b; Grünbein et al., 2018; Sobolev et al., 2020). Furthermore, the produced data must be of the highest possible quality and collected with maximum efficiency regarding sample and beamtime use (Konold et al., 2023). Thus, the effective and efficient investigation of liquid phase sample specimens with high-precision X-ray techniques still represents a unique challenge for XFELs (Konold et al., 2023).

At present, the gas-dynamic virtual nozzle (GDVN) is predominantly utilized for liquid sample injection in XFELs (DePonte et al., 2008; Vakili et al., 2020; Vakili et al., 2022; Knoška et al., 2020; Nazari et al., 2020; Nelson et al., 2016; Trebbin et al., 2014). In brief, a microscopic liquid stream is sheathed and accelerated by a stream of pressurized gas, forming a few-micron-wide liquid jet that is ejected in the vacuum (Gañán-Calvo, 1998; DePonte et al., 2008). The resulting cylindrical liquid jet must reach velocities on the order of tens of m s−1 to outpace radiation-induced sample explosions from consecutively incoming X-ray pulses (Stan et al., 2016; Wiedorn et al., 2018a; Wiedorn et al., 2018b). Today, these GDVNs are typically produced via high-resolution 3D printing, such as two-photon polymerization (Oberthuer et al., 2017; Knoška et al., 2020), yielding reproducible channel geometries that allow the minimization of sample flow rates, scattering background from the solvent, and reduce extreme sample consumption. However, this GDVN approach comes with longstanding issues severely impacting the success rate of XFEL experiments, such as vacuum compatibility issues, susceptibility to clogging and large background fluctuations (Konold et al., 2023). The latter challenge primarily stems from the X-ray beam pointing fluctuations hitting the cylindrical liquid jet: with typical jet diameters of ca 3 µm, slight deviations from the jet center result in significant changes of the X-ray interaction volume (Eggers & Villermaux, 2008).

An emerging method to overcome many of the above challenges is the use of liquid sheets that provide a consistent thickness over large areas (Ha et al., 2018; Koralek et al., 2018; Hoffman et al., 2022a; Hoffman et al., 2022b). Originally, free-flowing liquid sheets were generated using two impinging laminar jets resulting in smooth flows and stable jetting over long periods (Taylor, 1960; Bush & Hasha, 1999). More recently, glass-based microfluidic devices made via lithography were demonstrated utilizing gas acceleration to generate dramatically thinner sheets (Koralek et al., 2018; Hoffman et al., 2022a; Hoffman et al., 2022b). However, the use of sheet jets at XFELs has been far less prevalent due to high liquid and gas loads that complicate vacuum operation (Konold et al., 2023).

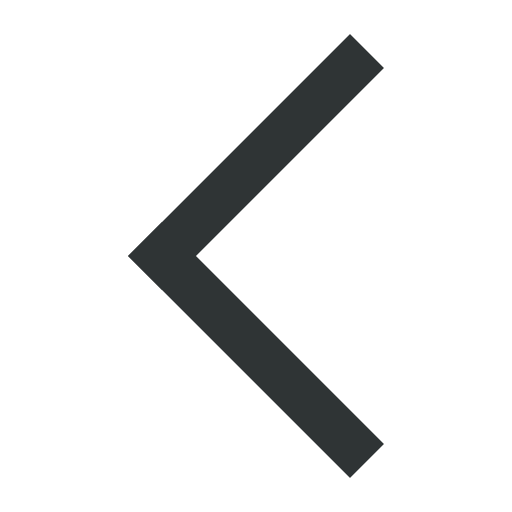

In the current issue of IUCrJ, Konold et al. present a refreshing and exciting approach addressing these above challenges: a 3D-printed gas-accelerating nozzle design for the generation of thin liquid sheets providing reproducible device fabrication, excellent stability, reduced liquid flow rates, low background and compatibility with high-repetition rate XFELs (Konold et al., 2023). The device performance has been thoroughly investigated at the European XFEL's SPB/SFX instrument using nanofocused X-ray scattering and highspeed video microscopy, yielding promising results for the interrogation of liquid samples at XFELs. Two of the most interesting results of this study are the large and even hit area and the achieved sheet thicknesses, as shown in Fig. 1. However, we will also shed light on some operational nuances that still have to be overcome.

![[me6252fig1]](https://www.iucr.org/__data/assets/image/0010/157798/me6252fig1.jpg)

Figure 1. Konold et al. present a 3D-printed nozzle for the generation of sheet jets. (A) CAD-design of the gas-accelerated nozzle design. (B) A microscopic image of the 3D-printed nozzle (ca 1.5 mm long). (C) Stroboscopic images of sheet jet explosion and void formation from two consecutive XFEL pulses (141 kHz). Image adapted from Konold et al. (2023).

First, the flatness and large area of the generated sheet vastly reduces sensitivity to X-ray beam pointing fluctuations improving scaling characteristics. The liquid sheet also overcomes longstanding difficulties of cylindrical jets, such as the distortion of pump laser focus properties or the calculation of take-off angles for X-ray photoelectron spectroscopy (Konold et al., 2023).

Second, the liquid sheet jets can be made very thin, ranging from a few hundred nanometres down to 60 nm. Compared with traditional GDVN jets, the ca 30-fold reduction in X-ray path length and 4-fold reduction in background offers intriguing experimental possibilities (Konold et al., 2023). Specifically, the background levels for X-ray scattering and spectroscopic investigations can be dramatically reduced, approaching the single-molecule scale. The minimal, wedge-like thickness variation can be used as a feature for swiftly adjusting the sample thickness on the fly by simply translating the nozzle. One must also not forget that the reduction in interaction volumes also reduces the impact from radiation-induced explosions, resulting in perturbation-free solution scattering data collection up to 564 kHz.

While the liquid flow rate is lower than previous sheet jet devices, it remains a challenge for scarce samples, such as proteins, because the liquid flow rate is still 3- to 5-fold higher than the GDVN it was compared with (Konold et al., 2023). Consequently, the vacuum compatibility of these devices remains a challenge, typically requiring differential pumping, cryo-trapping and/or heated sample catchers, which are not present at every beamline, thus limiting applicability (Konold et al., 2023). However, since most of the liquid volume is found in the much thicker rims, the authors make a few suggestions on how to potentially overcome these challenges, such as reducing channel dimensions or using carrier liquids, but those solutions will require further development (Hoffman et al., 2022a; Oberthuer et al., 2017). Another aspect to consider is the parabolic velocity profile across the sheet jet resulting from the gas focusing, which might make time-resolved experiments triggered by rapid mixing challenging to evaluate (Choo & Kang, 2002).

Although the study and evaluation were carried out thoroughly and in detail, showcasing the exciting applications for sheet jets, it is noteworthy that the experiments have been carried out only with 2-propanol. Thus, it remains to be seen how these devices will perform under realistic conditions, i.e. with aqueous samples and buffers, which are more prone to icing and clogging, especially under vacuum conditions.

While there is still some room for improvement, the liquid sheet technology remains an exciting addition to the liquid phase sample delivery toolset at XFELs because the tremendous experimental opportunities far outweigh the remaining few challenges. The stable, low background and large flat area of liquid sheets down to tens of nanometres of thickness not only offer great opportunities for various (soft) X-ray spectroscopies (Ekimova et al., 2015; Smith et al., 2020; Fondell et al., 2017), high-harmonic generation (Luu et al., 2018) and high-intensity laser plasma investigations (George et al., 2019) but also lead the way towards electron diffraction (Nunes et al., 2020; Yang et al., 2021) and small-/wide-angle X-ray solution scattering experiments (Blanchet et al., 2023). The nanometre-thin liquid sheets with low, stable background are especially attractive for experiments which benefit from small interaction volumes, such as fluctuation X-ray scattering (Kurta et al., 2017; Pande et al., 2018; Konold et al., 2023). With thicknesses approaching those of vitreous ice in cryo-electron microscopy, this study points towards the thrilling possibility of carrying out ultrafast single-particle solution scattering (Adrian et al., 1984; Kontziampasis et al., 2019; Klebl et al., 2020a; Klebl et al., 2020b).

References

Adrian, M., Dubochet, J., Lepault, J. & McDowall, A. W. (1984). Nature, 308, 32–36.

Bergmann, U., Kern, J., Schoenlein, R. W., Wernet, P., Yachandra, V. K. & Yano, J. (2021). Nat. Rev. Phys. 3, 264–282.

Blanchet, C. E., Round, A., Mertens, H. D. T., Ayyer, K., Graewert, M., Awel, S., Franke, D., Dörner, K., Bajt, S., Bean, R., Custódio, T. F., de Wijn, R., Juncheng, E., Henkel, A., Gruzinov, A., Jeffries, C. M., Kim, Y., Kirkwood, H., Kloos, M., Knoška, J., Koliyadu, J., Letrun, R., Löw, C., Makroczyova, J., Mall, A., Meijers, R., Pena Murillo, G. E., Oberthür, D., Round, E., Seuring, C., Sikorski, M., Vagovic, P., Valerio, J., Wollweber, T., Zhuang, Y., Schulz, J., Haas, H., Chapman, H. N., Mancuso, A. P. & Svergun, D. (2023). Commun. Biol. 6, 1057.

Bush, J. W. M. & Hasha, A. E. (1999). J. Fluid Mech. 511, 285–310.

Chapman, H. N., Fromme, P., Barty, A., White, T. A., Kirian, R. A., Aquila, A., Hunter, M. S., Schulz, J., DePonte, D. P., Weierstall, U., Doak, R. B., Maia, F. R. N. C., Martin, A. V., Schlichting, I., Lomb, L., Coppola, N., Shoeman, R. L., Epp, S. W., Hartmann, R., Rolles, D., Rudenko, A., Foucar, L., Kimmel, N., Weidenspointner, G., Holl, P., Liang, M., Barthelmess, M., Caleman, C., Boutet, S., Bogan, M. J., Krzywinski, J., Bostedt, C., Bajt, S., Gumprecht, L., Rudek, B., Erk, B., Schmidt, C., Hömke, A., Reich, C., Pietschner, D., Strüder, L., Hauser, G., Gorke, H., Ullrich, J., Herrmann, S., Schaller, G., Schopper, F., Soltau, H., Kühnel, K.-U., Messerschmidt, M., Bozek, J. D., Hau-Riege, S. P., Frank, M., Hampton, C. Y., Sierra, R. G., Starodub, D., Williams, G. J., Hajdu, J., Timneanu, N., Seibert, M. M., Andreasson, J., Rocker, A., Jönsson, O., Svenda, M., Stern, S., Nass, K., Andritschke, R., Schröter, C.-D., Krasniqi, F., Bott, M., Schmidt, K. E., Wang, X., Grotjohann, I., Holton, J. M., Barends, T. R. M., Neutze, R., Marchesini, S., Fromme, R., Schorb, S., Rupp, D., Adolph, M., Gorkhover, T., Andersson, I., Hirsemann, H., Potdevin, G., Graafsma, H., Nilsson, B. & Spence, J. C. H. (2011). Nature, 470, 73–77.

Choo, Y.-J. & Kang, B.-S. (2002). Phys. Fluids, 14, 622–627.

DePonte, D. P., Weierstall, U., Schmidt, K., Warner, J., Starodub, D., Spence, J. C. H. & Doak, R. B. (2008). J. Phys. D Appl. Phys. 41, 195505.

Eggers, J. & Villermaux, E. (2008). Rep. Prog. Phys. 71, 036601.

Ekimova, M., Quevedo, W., Faubel, M., Wernet, P. & Nibbering, E. T. J. (2015). Struct. Dyn. 2, 054301.

Fondell, M., Eckert, S., Jay, R. M., Weniger, C., Quevedo, W., Niskanen, J., Kennedy, B., Sorgenfrei, F., Schick, D., Giangrisostomi, E., Ovsyannikov, R., Adamczyk, K., Huse, N., Wernet, P., Mitzner, R. & Föhlisch, A. (2017). Struct. Dyn. 4, 054902.

Gañán-Calvo, A. M. (1998). Phys. Rev. Lett. 80, 285–288.

George, K. M., Morrison, J. T., Feister, S., Ngirmang, G. K., Smith, J. R., Klim, A. J., Snyder, J., Austin, D., Erbsen, W., Frische, K. D., Nees, J., Orban, C., Chowdhury, E. A. & Roquemore, W. M. (2019). High Power Laser Sci. Eng., 7, e50.

Grünbein, M. L., Bielecki, J., Gorel, A., Stricker, M., Bean, R., Cammarata, M., Dörner, K., Fröhlich, L., Hartmann, E., Hauf, S., Hilpert, M., Kim, Y., Kloos, M., Letrun, R., Messerschmidt, M., Mills, G., Nass Kovacs, G., Ramilli, M., Roome, C. M., Sato, T., Scholz, M., Sliwa, M., Sztuk-Dambietz, J., Weik, M., Weinhausen, B., Al-Qudami, N., Boukhelef, D., Brockhauser, S., Ehsan, W., Emons, M., Esenov, S., Fangohr, H., Kaukher, A., Kluyver, T., Lederer, M., Maia, L., Manetti, M., Michelat, T., Münnich, A., Pallas, F., Palmer, G., Previtali, G., Raab, N., Silenzi, A., Szuba, J., Venkatesan, S., Wrona, K., Zhu, J., Doak, R. B., Shoeman, R. L., Foucar, L., Colletier, J.-P., Mancuso, A. P., Barends, T. R. M., Stan, C. A. & Schlichting, I. (2018). Nat. Commun. 9, 3487.

Ha, B., DePonte, D. P. & Santiago, J. G. (2018). Phys. Rev. Fluids, 3, 114202.

Hoffman, D. J., Bechtel, H. A., Huyke, D. A., Santiago, J. G., DePonte, D. P. & Koralek, J. D. (2022a). Langmuir, 38, 12822–12832.

Hoffman, D. J., Van Driel, T. B., Kroll, T., Crissman, C. J., Ryland, E. S., Nelson, K. J., Cordones, A. A., Koralek, J. D. & DePonte, D. P. (2022b). Front. Mol. Biosci. 9, 1048932.

Klebl, D. P., Gravett, M. S. C., Kontziampasis, D., Wright, D. J., Bon, R. S., Monteiro, D. C. F., Trebbin, M., Sobott, F., White, H. D., Darrow, M. C., Thompson, R. F. & Muench, S. P. (2020a). Structure, 28, 1238–1248.e4.

Klebl, D. P., Monteiro, D. C. F., Kontziampasis, D., Kopf, F., Sobott, F., White, H. D., Trebbin, M. & Muench, S. P. (2020b). Acta Cryst. D76, 340–349.

Knoška, J., Adriano, L., Awel, S., Beyerlein, K. R., Yefanov, O., Oberthuer, D., Peña Murillo, G. E., Roth, N., Sarrou, I., Villanueva-Perez, P., Wiedorn, M. O., Wilde, F., Bajt, S., Chapman, H. N. & Heymann, M. (2020). Nat. Commun. 11, 657.

Konold, P. E., You, T., Bielecki, J., Valerio, J., Kloos, M., Westphal, D., Bellisario, A., Varma Yenupuri, T., Wollter, A., Koliyadu, J. C. P., Koua, F. H. M., Letrun, R., Round, A., Sato, T., Mészáros, P., Monrroy, L., Mutisya, J., Bódizs, S., Larkiala, T., Nimmrich, A., Alvarez, R., Adams, P., Bean, R., Ekeberg, T., Kirian, R. A., Martin, A. V., Westenhoff, S. & Maia, F. R. N. C. (2023). IUCrJ, 10, 662–670.

Kontziampasis, D., Klebl, D. P., Iadanza, M. G., Scarff, C. A., Kopf, F., Sobott, F., Monteiro, D. C. F., Trebbin, M., Muench, S. P. & White, H. D. (2019). IUCrJ, 6, 1024–1031.

Koralek, J. D., Kim, J. B., Brůža, P., Curry, C. B., Chen, Z., Bechtel, H. A., Cordones, A. A., Sperling, P., Toleikis, S., Kern, J. F., Moeller, S. P., Glenzer, S. H. & DePonte, D. P. (2018). Nat. Commun. 9, 1353.

Kraus, P. M., Zürch, M., Cushing, S. K., Neumark, D. M. & Leone, S. R. (2018). Nat. Rev. Chem. 2, 82–94.

Kurta, R. P., Donatelli, J. J., Yoon, C. H., Berntsen, P., Bielecki, J., Daurer, B. J., DeMirci, H., Fromme, P., Hantke, M. F., Maia, F. R. N. C., Munke, A., Nettelblad, C., Pande, K., Reddy, H. K. N., Sellberg, J. A., Sierra, R. G., Svenda, M., van der Schot, G., Vartanyants, I. A., Williams, G. J., Xavier, P. L., Aquila, A., Zwart, P. H. & Mancuso, A. P. (2017). Phys. Rev. Lett. 119, 158102.

Luu, T. T., Yin, Z., Jain, A., Gaumnitz, T., Pertot, Y., Ma, J. & Wörner, H. J. (2018). Nat. Commun. 9, 3723.

Nazari, R., Zaare, S., Alvarez, R. C., Karpos, K., Engelman, T., Madsen, C., Nelson, G., Spence, J. C. H., Weierstall, U., Adrian, R. J. & Kirian, R. A. (2020). Opt. Express, 28, 21749–21765.

Nelson, G., Kirian, R. A., Weierstall, U., Zatsepin, N. A., Faragó, T., Baumbach, T., Wilde, F., Niesler, F. B. P., Zimmer, B., Ishigami, I., Hikita, M., Bajt, S., Yeh, S.-R., Rousseau, D. L., Chapman, H. N., Spence, J. C. H. & Heymann, M. (2016). Opt. Express, 24, 11515–11530.

Neutze, R., Wouts, R., van der Spoel, D., Weckert, E. & Hajdu, J. (2000). Nature, 406, 752–757.

Nunes, J. P. F., Ledbetter, K., Lin, M., Kozina, M., DePonte, D. P., Biasin, E., Centurion, M., Crissman, C. J., Dunning, M., Guillet, S., Jobe, K., Liu, Y., Mo, M., Shen, X., Sublett, R., Weathersby, S., Yoneda, C., Wolf, T. J. A., Yang, J., Cordones, A. A. & Wang, X. J. (2020). Struct. Dyn. 7, 024301.

Oberthuer, D., Knoška, J., Wiedorn, M. O., Beyerlein, K. R., Bushnell, D. A., Kovaleva, E. G., Heymann, M., Gumprecht, L., Kirian, R. A., Barty, A., Mariani, V., Tolstikova, A., Adriano, L., Awel, S., Barthelmess, M., Dörner, K., Xavier, P. L., Yefanov, O., James, D. R., Nelson, G., Wang, D., Calvey, G., Chen, Y., Schmidt, A., Szczepek, M., Frielingsdorf, S., Lenz, O., Snell, E., Robinson, P. J., Šarler, B., Belšak, G., Maček, M., Wilde, F., Aquila, A., Boutet, S., Liang, M., Hunter, M. S., Scheerer, P., Lipscomb, J. D., Weierstall, U., Kornberg, R. D., Spence, J. C. H., Pollack, L., Chapman, H. N. & Bajt, S. (2017). Sci. Rep. 7, 44628.

Pande, K., Donatelli, J. J., Malmerberg, E., Foucar, L., Bostedt, C., Schlichting, I. & Zwart, P. H. (2018). Proc. Natl Acad. Sci. USA, 115, 11772–11777.

Smith, A. D., Balčiūnas, T., Chang, Y.-P., Schmidt, C., Zinchenko, K., Nunes, F. B., Rossi, E., Svoboda, V., Yin, Z., Wolf, J.-P. & Wörner, H. J. (2020). J. Phys. Chem. Lett. 11, 1981–1988.

Sobolev, E., Zolotarev, S., Giewekemeyer, K., Bielecki, J., Okamoto, K., Reddy, H. K. N., Andreasson, J., Ayyer, K., Barak, I., Bari, S., Barty, A., Bean, R., Bobkov, S., Chapman, H. N., Chojnowski, G., Daurer, B. J., Dörner, K., Ekeberg, T., Flückiger, L., Galzitskaya, O., Gelisio, L., Hauf, S., Hogue, B. G., Horke, D. A., Hosseinizadeh, A., Ilyin, V., Jung, C., Kim, C., Kim, Y., Kirian, R. A., Kirkwood, H., Kulyk, O., Küpper, J., Letrun, R., Loh, N. D., Lorenzen, K., Messerschmidt, M., Mühlig, K., Ourmazd, A., Raab, N., Rode, A. V., Rose, M., Round, A., Sato, T., Schubert, R., Schwander, P., Sellberg, J. A., Sikorski, M., Silenzi, A., Song, C., Spence, J. C. H., Stern, S., Sztuk-Dambietz, J., Teslyuk, A., Timneanu, N., Trebbin, M., Uetrecht, C., Weinhausen, B., Williams, G. J., Xavier, P. L., Xu, C., Vartanyants, I. A., Lamzin, V. S., Mancuso, A. & Maia, F. R. N. C. (2020). Commun. Phys. 3, 97.

Stan, C. A., Milathianaki, D., Laksmono, H., Sierra, R. G., McQueen, T. A., Messerschmidt, M., Williams, G. J., Koglin, J. E., Lane, T. J., Hayes, M. J., Guillet, S. A. H., Liang, M., Aquila, A. L., Willmott, P. R., Robinson, J. S., Gumerlock, K. L., Botha, S., Nass, K., Schlichting, I., Shoeman, R. L., Stone, H. A. & Boutet, S. (2016). Nat. Phys. 12, 966–971.

Taylor, G. (1960). Proc. R. Soc. London Ser. A, 259, 1–17.

Trebbin, M., Krüger, K., DePonte, D., Roth, S. V., Chapman, H. N. & Förster, S. (2014). Lab Chip, 14, 1733–1745.

Vakili, M., Vasireddi, R., Gwozdz, P. V., Monteiro, D. C. F., Heymann, M., Blick, R. H. & Trebbin, M. (2020). Rev. Sci. Instrum. 91, 085108.

Vakili, M., Bielecki, J., Knoška, J., Otte, F., Han, H., Kloos, M., Schubert, R., Delmas, E., Mills, G., de Wijn, R., Letrun, R., Dold, S., Bean, R., Round, A., Kim, Y., Lima, F. A., Dörner, K., Valerio, J., Heymann, M., Mancuso, A. P. & Schulz, J. (2022). J. Synchrotron Rad. 29, 331–346.

Wiedorn, M. O., Awel, S., Morgan, A. J., Ayyer, K., Gevorkov, Y., Fleckenstein, H., Roth, N., Adriano, L., Bean, R., Beyerlein, K. R., Chen, J., Coe, J., Cruz-Mazo, F., Ekeberg, T., Graceffa, R., Heymann, M., Horke, D. A., Knoška, J., Mariani, V., Nazari, R., Oberthür, D., Samanta, A. K., Sierra, R. G., Stan, C. A., Yefanov, O., Rompotis, D., Correa, J., Erk, B., Treusch, R., Schulz, J., Hogue, B. G., Gañán-Calvo, A. M., Fromme, P., Küpper, J., Rode, A. V., Bajt, S., Kirian, R. A. & Chapman, H. N. (2018a). IUCrJ, 5, 574–584.

Wiedorn, M. O., Oberthür, D., Bean, R., Schubert, R., Werner, N., Abbey, B., Aepfelbacher, M., Adriano, L., Allahgholi, A., Al-Qudami, N., Andreasson, J., Aplin, S., Awel, S., Ayyer, K., Bajt, S., Barák, I., Bari, S., Bielecki, J., Botha, S., Boukhelef, D., Brehm, W., Brockhauser, S., Cheviakov, I., Coleman, M. A., Cruz-Mazo, F., Danilevski, C., Darmanin, C., Doak, R. B., Domaracky, M., Dörner, K., Du, Y., Fangohr, H., Fleckenstein, H., Frank, M., Fromme, P., Gañán-Calvo, A. M., Gevorkov, Y., Giewekemeyer, K., Ginn, H. M., Graafsma, H., Graceffa, R., Greiffenberg, D., Gumprecht, L., Göttlicher, P., Hajdu, J., Hauf, S., Heymann, M., Holmes, S., Horke, D. A., Hunter, M. S., Imlau, S., Kaukher, A., Kim, Y., Klyuev, A., Knoška, J., Kobe, B., Kuhn, M., Kupitz, C., Küpper, J., Lahey-Rudolph, J. M., Laurus, T., Le Cong, K., Letrun, R., Xavier, P. L., Maia, L., Maia, F. R. N. C., Mariani, V., Messerschmidt, M., Metz, M., Mezza, D., Michelat, T., Mills, G., Monteiro, D. C. F., Morgan, A., Mühlig, K., Munke, A., Münnich, A., Nette, J., Nugent, K. A., Nuguid, T., Orville, A. M., Pandey, S., Pena, G., Villanueva-Perez, P., Poehlsen, J., Previtali, G., Redecke, L., Riekehr, W. M., Rohde, H., Round, A., Safenreiter, T., Sarrou, I., Sato, T., Schmidt, M., Schmitt, B., Schönherr, R., Schulz, J., Sellberg, J. A., Seibert, M. M., Seuring, C., Shelby, M. L., Shoeman, R. L., Sikorski, M., Silenzi, A., Stan, C. A., Shi, X., Stern, S., Sztuk-Dambietz, J., Szuba, J., Tolstikova, A., Trebbin, M., Trunk, U., Vagovic, P., Ve, T., Weinhausen, B., White, T. A., Wrona, K., Xu, C., Yefanov, O., Zatsepin, N., Zhang, J., Perbandt, M., Mancuso, A. P., Betzel, C., Chapman, H. & Barty, A. (2018b). Nat. Commun. 9, 4025.

Yang, J., Nunes, J. P. F., Ledbetter, K., Biasin, E., Centurion, M., Chen, Z., Cordones, A. A., Crissman, C., Deponte, D. P., Glenzer, S. H., Lin, M.-F., Mo, M., Rankine, C. D., Shen, X., Wolf, T. J. A. & Wang, X. (2021). Phys. Chem. Chem. Phys. 23, 1308–1316.

This article was originally published in IUCrJ (2023). 10, 638–641.

![me6252thumbnail [me6252thumbnail]](https://www.iucr.org/__data/assets/image/0009/157797/me6252thumbnailmodified.jpg)

![[me6252fig1]](https://www.iucr.org/__data/assets/image/0010/157798/me6252fig1.jpg)