IUCr activities

Standards for Rietveld Refinement

The report of the first phase of the Round Robin on Rietveld Refinement project of the IUCr Commission on Powder Diffraction was published in J. Appl. Cryst. 25, 589-610 (1992). The following paragraph is excerpted from the abstract for that paper.

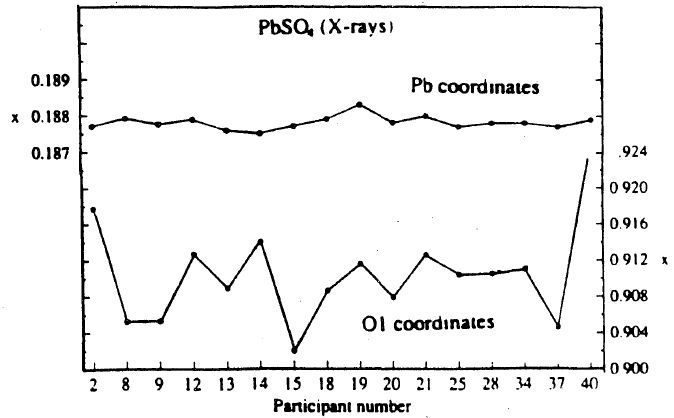

Variation of the refined atomic coordinates of the Pb and O atoms. From J. Appl. Cryst. 25, 589 (1992).

Variation of the refined atomic coordinates of the Pb and O atoms. From J. Appl. Cryst. 25, 589 (1992).

The aims of the project were: (i) to evaluate a cross section of currently used Rietveld refinement software; (ii) to examine the range and effect of various strategies of Rietveld refinement; and (iii) to assess the precision and accuracy (spread) of the parameters derived by Rietveld analysis. 23 participants provided 18 refinements with the X-ray data and 20 refinements with the neutron data using 11 different Rietveld analysis programs. The wide variation in the values of the agreement indices obtained in these studies of the same data sets highlights the need for standardization. The major factors limiting the accuracy of the derived PbSO4 crystal structure parameters were: (i) use of insufficiently flexible peak shape and/or background functions; (ii) elimination of the high-angle diffraction data from the refinement; (iii) inclusion of an insufficiently wide range of diffraction angles on either side of the centroid of each peak during the step intensity calculation; and, additionally for X-rays; (iv) simultaneous release of the O-atom site-occupancy and displacement parameters. Rietveld analysis of the PbSO4 X-ray powder diffraction data provided atomic coordinates and isotropic displacement parameters for the Pb and S atoms in reasonable agreement with the values derived from a single-crystal study. On the other hand, the "light" O-atom parameters show relatively poor precision and have a disconcertingly wide spread of values about the weighted mean (viz range 0.12-0.19 Å). This investigation indicates that results of possibly high precision but low accuracy are not uncommon in Rietveld analysis. The disparity between individual refinements can be expected to increase further when, unlike here, the analyses are undertaken using data sets collected under diverse experimental conditions.

R.J. Hill, the coordinator of the project, analyzed the data gathered and prepared and revised the report eventually endorsed by the full commission.

Hill is now analyzing the results from the second phase, in which participants collected their own data on a sample of monoclinic zirconia provided to them. Both studies have revealed worker-to-worker disparities greater than anticipated, and efforts are being made to pinpoint some of the causes of these disparities. The CPD has under consideration a "Round Robin on Crystallite Size and Microstrain" to be carried out jointly with the IUCr Commission on ICDD. Questions about the feasibility of such a project are now being addressed. R.L. Snyder at the New York State College of Ceramics, Alfred U., is taking the lead role for the ICDD in this project.

The CPD has taken a leading role in the further development of the CIF/STAR format system for use with powder diffraction data and in promoting it as the universal standard for the storage and exchange of such data. In addition to being very flexible in accommodating different types of data, the CIF /STAR system has the advantage that it retains all pertinent details of the experiment. Thus it offers the possibility of recapturing the original raw data from the "processed" data obtained from various national and international facilities, each with its own protocol. The ICDD has adopted the system for future databases and is cooperating with the CPD in the further development needed. The lead person for the CPD involvement is Dr. J.I. Langford, and for the ICDD Dr. B.H. Toby.